WATER TREATMENT SOLUTIONS

MVX Hi-Tech Mission Statement: To be the #1 worldwide provider of advanced water treatment systems known for the quality of our systems, customer service, and business integrity. MVX Hi-Tech has provided a superior product to its distributors and customers. At MVX Hi-Tech we strive to continually update and produce new top-quality products that will allow our distributors and costumers the best design , install and services in water treatment. MVX Hi-Tech developed its pioneering range of water treatment products

Small Scale Waste Water Treatment System

Small Scale Waste Water Treatment System

Quantity of domestic waste water , especially the quantity of gray water and pollutant loads , are known to vary with lifestyles , living standards and other factors . The daily amount of domestic waste water ranges fom 200-250 liters per person .Pollutant loads of domestic waste water is 40-50 g of BOD ,10-12g of T- N and 1.2 – 1.5 of T- P per capita per day . The amount of waste water and pollutant loads for the design of small scale waste water as follow.

| Limit values | ||

| COD (chemical oxygen demand) | 286 | mg / L |

| BOD (biochemical oxygen demand) | 200 | mg / L |

| SS (suspended solids) | 150 | mg / L |

| NH4-N N total | 40 | mg / L |

| PO4-P P total | 5.0 | mg / L |

Anaerobic – Aerobic waste water treatment system

Anaerobic – Aerobic waste water treatment system

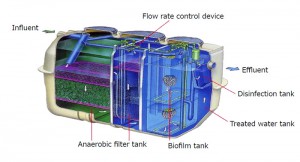

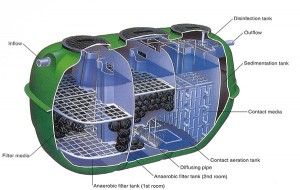

Treatment process Anaerobic – Aerobic system

- A naerobic-Aerobic bed system comprises four chambers. The wastewater first enters the first chamber. Solids sink to the bottom here.Floating particles is moving to the ceond chamber.

- The wastewater enters the second chamber through the transfer pipe.Actual biological cleaning by microorganisms occurs here. Those microorganisms stick to the carrier material, which is made of plastic. The carrier material has a very large surface. The bacteria needed for purification stick to the carrier material .So that the bacteria receive enough aoxygen , the is regularly streamed with air. An air compressor is used for this purpose, which is installed in the cellar or in the garden outside the reservoir.

- Then the wastewater enters the third chamber for final treatment. The remaining solids settle there and they are back to the second chamber from here. The purified wastewater disinficted and can now be fed into a discharge system (stream, river, sea) or reused

Moving bed -Biofilm waste-water treatment system

Simple and cost-effective With the development of the Moving Bed system, one air compressor, a pipe ventilator, sludgeremoval and the carrier A further advantage of the Moving Bed system is that the high