Thermal Reflective Liquid Paint

ANZ GLASS COATING

Architects, designer and builders have more choices of the glass today than ever before .Those choices can make a tremendous difference in your project`s cost , energy efficiency and environmental impact . So you need accurate , details information -including performance capabilities of glass insulation . This brochure provide the technical information , coating construction , proper handling , maintenance and cleaning of the glass before and after coating.

Architects, designer and builders have more choices of the glass today than ever before .Those choices can make a tremendous difference in your project`s cost , energy efficiency and environmental impact . So you need accurate , details information -including performance capabilities of glass insulation . This brochure provide the technical information , coating construction , proper handling , maintenance and cleaning of the glass before and after coating.

Types of Glass

Getting the right type of glass – and the best quality insulat ion t ype – can be critical to the success of your project. This section defines the various kinds of glass, how theyʼre made, and their st rengths and characteristics. I t also diagrams construct ion techniques to show how diff erent glass types can be combined for the desired heat , light and insulation properties.

ANNEALED GLASS

Float glass (also called “flat” glass) that has not been heat-strengthened or tempered is annealed glass. Annealing float glass is the process of controlled cooling to prevent residual stress in the glass and is an inherent operation of the float glass manufacturing process. A nnealed glass can be cut, machined, drilled, edged and polished.

HEAT-STRENGTHENED GLASS

Heat-strengthened (HS ) glass has been subjected to a heating and cooling cycle and is generally twice as strong as annealed glass of the same thickness and configuration. H S glass must achieve residual surface compression between 3,500 and 7,500 PSI for 6mm glass, according to HS glass has greater resistance to thermal loads than annealed glass and, when bro ken the fragments are typically larger than those of fully tempered glass and initially may remain in the glazing strengthened glass is not a safety glass product as defined by the various code organizations.

This type of glass is intended for general glazing, where additional strength is desired to withstand wind load and thermal stress. It does not require the strength of fully tempered glass, and is intended for applications that do not specifically require a safety glass product. When heattreated glass is necessary, Industries recommends the use of heat-strengthened glass for applications that do not specifically require a safety glass product. H S glass cannot be cut or drilled after heat-strengthening and any alterations, such as edge-grinding, sandblasting or acidetching, can cause premature failure.

TEMPERED GLASS

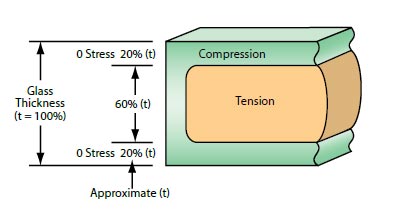

Fully tempered glass is approximately four times stronger than annealed glass of the same thickness and configuration, and residual surface compression must be over 10,000 PS I for 6mm, according to ASTM C 1048. or thicker glass standards. When broken, it will break into many relatively small fragments, which are less likely to cause serious injury . The typical process to produce tempered glass involves heating the glass to over 1,000 degrees F, then rapidly cooling to lock the glass surfaces in a state of

compression and the core in a state of tension as shown in the diagram.

Tempered glass is often referred to as “safety glass” because it meets the require ments of the various code o rganizations that set standards for safety glass. This type of glass is intended for general glazing, and safety glazing such as sliding doo rs, storm doors, building entrances, bath and shower enclosures, interior partitions and other uses requiring superior strength and safety properties. Tempered glass cannot be cut or drilled after tempering, and any alterations, such as edge-grinding , sandblastin g or acid-etching, can cause premature failure.

LAMINATED GLASS

Laminated glass is two or m ore lites (pieces) of glass permanently bonded to gether with one or more plastic interlayers ( PV B ) using heat and pressure The. glass and interlayers can be a variety of colo rs and thicknesses desi gned to meet buildin g code standards and requirements as necessar y. Laminated glass can be broken, but the fragments will tend to adhere to the plastic layer and remain largely intact, reducing the risk of injur y .L aminated glass is considered “safety glass” because it meets the requirements of the various code organizations that set standards for safet y. Heatstrengthened and tempered glass can be incorporated into laminated glass units to further strengthen the impact resistance. Hurricane resistance, the need for bomb blast protection, sound attenuation and ballistic or forced-entry security concerns are all primary uses for laminated glass. For complete industry-accepted information about laminated glass

Insulating glass refers to two o r more lites of glass sealed around the edges with an air space between, to form a single unit. Commonly referred to as an “IG unit,” insulating glass is the most effective way to reduce air-to-air heat transfer through the glazing. When used in conjunction with ANZ reflective glass coatings, IG units become effective means to conserve energy and comply with energy codes. The most comm on architectural insulating glass unit configuration is

1/4″ glass/ 1/2″ air space/ 1/4″ glass.

As ANZ coatings have become better at reducing ai r-to-air heat transfer, spacer technology has become the focus of incremental thermal improvements. Typical commercial spacers are composed of formed aluminum filled with desiccant to absorb any residual moisture inside the IG unit, thus reducin g potential condensation. While this is a structurally strong material, the aluminum-to- glass contact point is a very efficient thermal conductor and can increase the potential for temperature differential between the center of glass and the ed ge of glass, which can lead to condensation and reduces the unitʼs overall U-Value.